Comparing Multiport Bicolor Gauges, Transparent Gauges, and Reflex Gauges for Boiler Applications

Accurate level measurement is crucial for boilers in industries like power generation, oil & gas, and chemical processing, where maintaining optimal liquid levels in boilers is vital for safety and operational efficiency.

For steam boilers, selecting the right level gauge ensures precise monitoring and reliable performance. Among the widely used level gauges, Multiport Bicolor Gauges, Transparent Gauges, and Reflex Gauges each offer unique benefits and limitations. Understanding their differences helps in making an informed choice for specific applications.

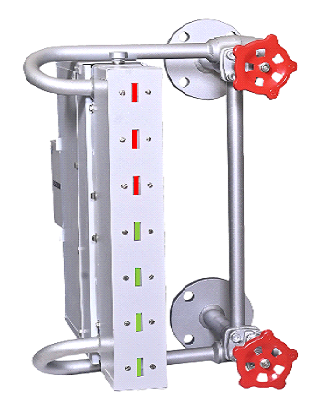

1. Multiport Bicolor Gauges: Advanced Visibility & Reliable Performance

Key Features:

- Rugged & Robust Design – Built to withstand extreme boiler conditions, ideal for high-pressure applications with extended durability.

- Dual-Color Display – Red for steam, green for water enable quick differentiation and unmistakable level indication

- Enhanced Visibility – Equipped with LED illumination for easy reading even in low-light conditions.

- Superior Protection – Mica sheet protection prevents glass erosion from steam and water.

- Easy Maintenance – Individual port assembly allows quick installation and hassle-free glass replacement.

- Customization & Compliance – Available in customized center-to-center distances with IBR certification.

Applications:

Widely used in boiler drum applications, Multiport Bicolor Level Gauges are best suited for medium- to high-pressure boilers, offering direct and precise liquid level indication.

Advantages:

- Superior visibility from any distance and location.

- Minimal human error with intuitive dual-color indication.

- Enhanced safety & compliance with industry standards.

Limitations:

- Level between ports is not directly visible.

- Visibility may be affected by steam condensation or contamination.

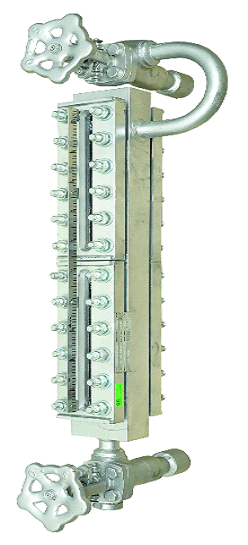

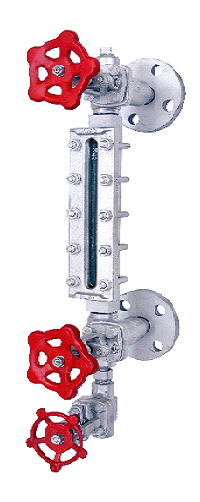

2. Transparent Gauges: Clarity & Versatility

Key Features:

- Dual flat glasses on either side provide direct liquid visualization.

- High-Pressure Resistance – Ideal for monitoring water/steam at high temperatures and pressures.

- Mica Sheet Protection – Prevents glass erosion from steam and water.

Optional Illuminator – Improves visibility in low-light environments.

Applications:

Commonly used in boiler drum applications, transparent gauges are suitable for medium-pressure boilers that require direct liquid level indication.

Advantages:

- Durable and rugged for high-temperature and pressure applications.

- Direct liquid visualization enhances monitoring accuracy.

- Suitable for colored, colorless, and interface liquid level measurement.

Limitations:

- Visibility may be affected by steam condensation or contamination.

3. Reflex Gauges: Simplicity & Cost-Effectiveness

Key Features:

- Prismatic Glass Design – Uses light reflection to differentiate liquid and vapor phases.

- Distinct Level Indication – Liquid appears dark, while vapor/steam appears silvery white.

Applications:

Widely used in low- to medium-pressure applications, reflex gauges offer a cost-effective solution for liquid level indication.

Advantages:

- Robust and durable for industrial use.

- Direct and clear liquid indication.

- Economical compared to transparent and multiport bicolor gauges.

Limitations:

- Not suitable for colored or interface liquids.

- Not recommended for high-pressure applications.

Comparison Table

|

Feature |

Multiport Bicolor Gauge |

Transparent Gauge |

Reflex Gauge |

|

Visibility |

Red (steam), Green (water); visible from a distance |

Direct liquid indication; visible from close range |

Light/dark phase contrast; visible from close range |

|

Applications |

High-pressure boiler drums |

Medium-pressure boilers, colored, colorless, and interface liquids |

Low- to medium-pressure applications, colorless liquids & water |

|

High-Pressure Suitability |

Excellent |

Moderate |

Not recommended |

|

Boiler Pressure Rating |

Up to 120 kg/cm² |

Up to 80 kg/cm² |

Up to 25 kg/cm² |

|

Durability |

High (with mica protection) |

High (with mica protection) |

Limited |

|

Cost |

Higher investment |

Moderate |

Cost-effective |

|

Ease of Use |

Clear and distinct visibility |

Requires illumination in low light |

No illumination needed |

Conclusion

Choosing the right level gauge depends on specific application requirements and operational conditions. Knowing the strengths and limitations of each gauge type helps you to choose right instrument for the application. In case of any assistance, please reach out to us to choose the right solution for your needs.