Industrial Safety and Level Measurement: Does it go hand-in-hand?

Safety is the most important and fundamental factor in any work environment, the concept of which has evolved along with industrial development. Apart from being part of the fundamental right to life and safety, following safety measures also increase work efficiency. Identifying and mitigating risks in work environment by choosing the best safety methods and tools for your factory/workplace results in less downtime, reduced cost and also saves everyone from the mental trauma of an accident. No amount of money can make up for a loss of human life or disabling injury.

The history of National Safety day dates back to December 11 to 13, 1965 when the Union ministry of labor and employment organized a conference on industrial safety for the first time. During the conference, a need was felt to establish safety councils on national and state levels. The campaign for the National Safety Day was born half a decade later, on March 4, 1972.

The theme for this year’s national safety day is “road safety”. The celebrations this year have also been spread over a week and National Safety Week was observed from March 4 to March 10.

Another predominant theme which demands our attention is industrial safety and the influence of level measurement and process automation on the same.

While working in an industrial environment, accurate level measurements is of utmost importance to ensure safety, save time & money, and optimize the performance of your plant and its processes. For smooth functioning of processes it is important to invest in measurement systems which are designed for precision and accuracy.

Inaccurate level measurements can cause severe safety risks while dealing with hazardous materials in the industrial workspace.

Chemicals that are stored in tanks/vessels can easily seep through, corrode, overflow or inflame and cause severe problem for workers as well as the environment. To save from such troubles, automated level measurement and control instruments is what is needed. Manual methods of monitoring level, carries a risk factor resulting into human error and injury. Even a miniscule particle of flammable dust can burst into fire igniting a dust explosion and injure workers.

Pune Techtrol Ltd. provides you with a reliable solution and guarantees to save you, your workers and the environment from such potential hazards.

Our instruments are designed to meet all the safety standards. We have wide range of approved, verified, certified and tested products which will meet all the safety standards and environmental norms and regulations.

We offer a wide array of robust flame proof ATEX certified products which will stand the test of time and extreme conditions. Our IBR certified instruments are suitable for high pressure and high temperature applications. Most of our instruments are CE certified which meets EU standards for health, safety, and environmental protection.

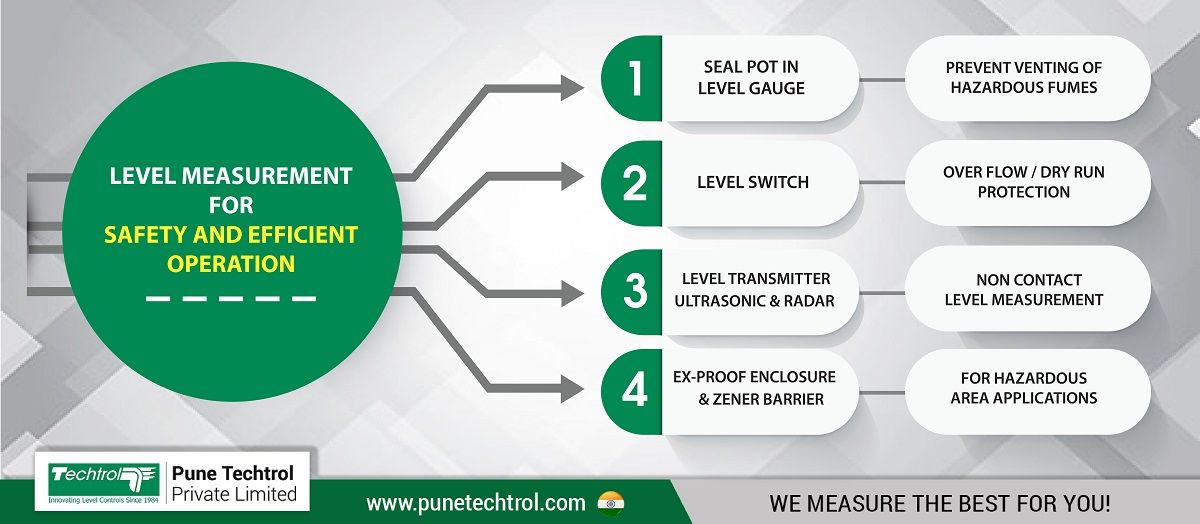

Level Measurement technologies that we provide for your efficient operation and safety include:

- Level Gauges, suitable for liquid level indication in high temp and pressure vessels

- Level switches based on Archimedes principle, conductivity, magnetism are used for overflow detection, control and automation.

- Level transmitters for continuous monitoring and automation

- Non-contact type ultrasonic and radar transmitters with PVDF MOC transducer/antenna for corrosive liquid applications.

- Zener barriers are provided to drive intrinsically safe field instruments in hazardous area.

- Added feature like seal pot assembly is provided in float & board, float & tape and float & dial gauge to prevent venting of corrosive fume in air.

A lot more is in store for you, visit product page on our website to know more.