Six Challenges Faced by Chemical Industries for measurement and control of level

Best-In-Class Level Measurement and Control Instruments by Pune Techtrol Owing To meticulously Engineered Instruments!

Continuous upgrading of environment & safety standards, stringent quality requirements of products and cost effective operationsare some of the varied and complex challenges that chemical industries have to deal with.To meet the ever-increasing demands of customers the chemical industries have to advancetechnologically to maintain lead in the market withreliable products. For implementation of advanced technology, one needs to have expert know-how of the instrumentation and automation market, to choose the proper instruments required for the level measurement of liquid and solid materials.

Pune Techtrol is the perfect companion offering acomprehensive range of products inlevel measurements and control instrumentsas well as expert know-howfor process automation. Chemical industries need accurate and reliable level measurement and control instruments to overcome following challenges normally encountered in their operations.

1. Corrosive liquids and environment

Handling of corrosive and aggressive liquids is inevitable in chemical industries. The chemicals needed to be handled may have strong acidic and strong alkaline properties. Very often corrosive fumes may be present in the storage tanks/vessels. Level measuring instruments installed on such storage tanks must be able to function accurately for long periods. Mechanisms of high and low-level monitoring, instruments must be able to sustain corrosive environments.Manual methods of monitoring level have a risk factor resulting into human injury.To assure the smooth functioning of processes, it is essential to design instruments with precision. The cutting-edge technology provided in Pune Techtrol instruments is highly precise.Measurement Technologies:

- Various “Material of Construction (MOC)” of thelevelmeasuring instruments such as SS304/316/ PP/ PVDF, PTFE coated with SS are provided to suit the corrosive nature of chemicals.

- Direct reading level gauges use stainless steel, PVDF, Teflon as MOC, particularly for corrosive and toxic chemicals.

2. Safety Norms and Regulations

Safety is a critical parameter inchemical industries. Some plants in chemical industries have inherent dangers because of the reactive chemicals stored in the tanks/vessels. Measurement and control operations in respect of such processes must have minimal human involvement and hence have to be automatic or remotely controlled. Some chemicals are flammable and can cause fire hazard. To comply with safety requirements,Techtrolinstruments are designed to meet all the safety standards. Pune Techtrolhas wide range of approved,verified, certified and tested products thatmeet all the safety standards and environmental norms and regulations.

3. Materials having Different values of viscosity, specific gravity, dielectric constant

Values of viscosity,specific gravity, dielectric constant of materials whose levels are to be monitored are very important in design and selection of appropriate instruments for particular operation.Techtrol manufactures level measuring instruments based on various principles. While designing and manufacturing the instruments the precise values of these parameters must be available from the users. Accurate values of viscosity, specific gravity, dielectric constants in turn ensure accuracy and reliability of the level monitoring instruments.Measurement Technologies:

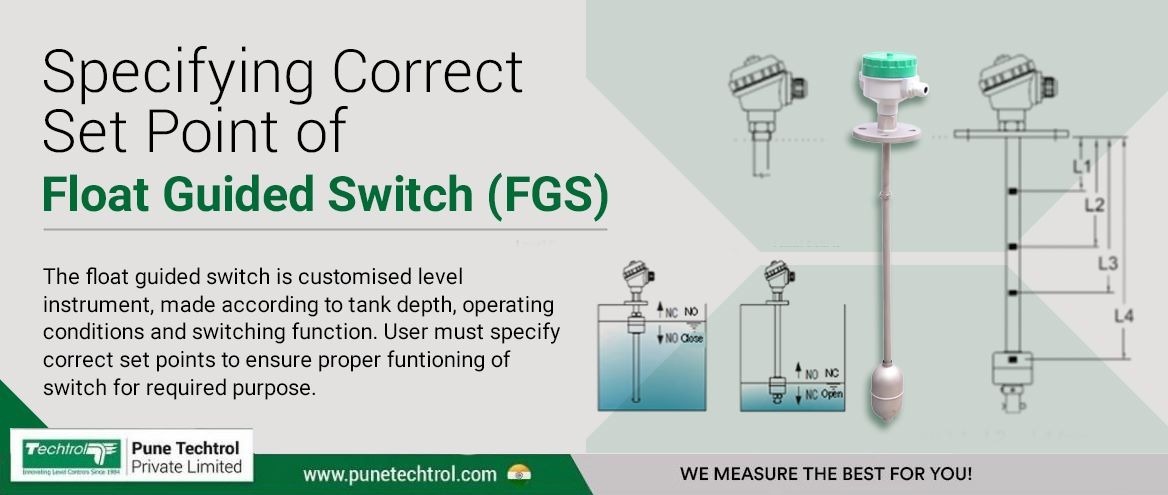

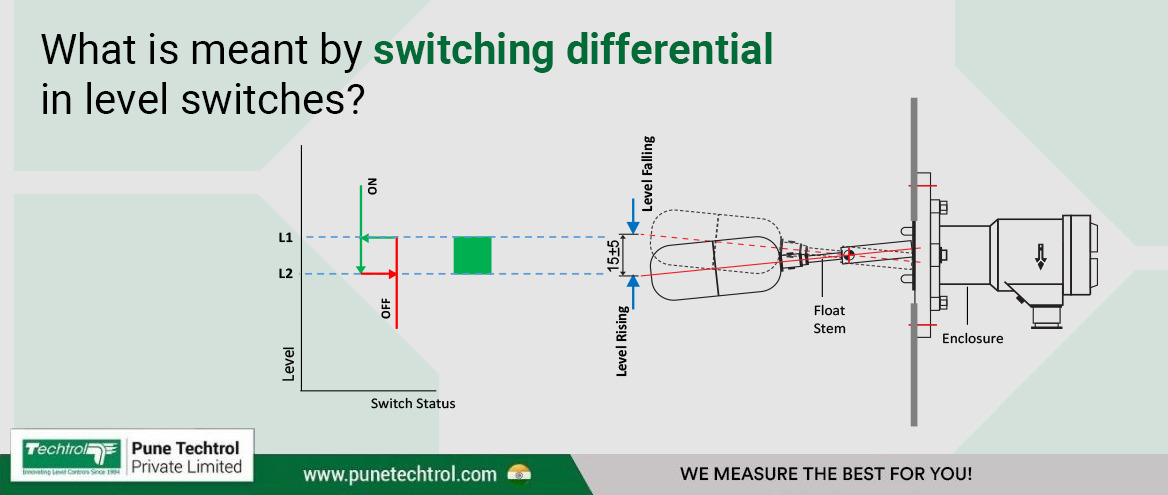

- Float type switch are based on Archimedes principle where density is important.

- In case of capacitance & radar type instruments, dielectric constant must be known.

4. High temperature & pressure conditions

In chemical industry there are endothermic and exothermic processes where high temperature & pressure conditions can occur. Working in such critical conditions, plant operators require accurate &reliable solutions for monitoring applications.In such varying temperature and pressure and the aggressive media, Techtrollevel measurements and control instrumentsare capable of working satisfactorily under such conditions

Measurement Technologies:

- Appropriate selection of material with sufficient mechanical strength is ensured for the instruments subjected to conditions of high temperature and pressure.

- Direct reading level gauges are tested for 1.5 times the operating pressure and certified by Inspectorate of Boilers wherever necessary.

5. Presence of fumes, dust and fire hazards

The tanks storing fly-ash haveextremely hot and dusty environment. Also, some chemicals/ materials can generate fumes which may lead to fire hazards in thechemical plant. When a fine dust suspended in air is ignited a dust explosion occurs which causes a very rapid burning and can injure people.The results of the instruments must be helpful to avoid the undesired conditions. The level instruments provided by Pune Techtrol come with a robustflameproof housing and are designed to provide accurate results in extreme conditions.

Measurement Technologies:

- For fuming liquids, seal pots are provided in FBG, FDG & FTG.

- For hazardous applications instruments are provided with flame-proof & ATEX certified enclosures

- Non-contact type instruments based on radarprinciple have antenna made up of PVDF material..

- Selection between contact and non-contact type radar is done by taking into consideration the presence of dust/fumes and dielectric constants of the chemical materials.

- Zener barriers are provided for isolation wherever required.

6. Improvement in Plant Efficiency

By virtue of their accuracy and reliability Techtrol level measuring instruments play vital role in improving operational efficiency of the plant. Techtrol uses modern technology to meet the challenge of continuous improvement in level measurement in turn helping the industry to improve product quality & efficiency. Following instruments are examples of such advanced technology.

- Ultrasonic transmitters an guided wave radar

- Radar type level transmitter using FMCW technology

- Magnetostrictive transmitters

- Displacer type transmitters

A final word

Pune Techtrol, a leading manufacturer in the field has set the benchmark by its precise and reliable instruments.The team of professional and skilled engineers of Pune Techtrol, who have expertise in theselection of the appropriate level measurement and control instruments, take into account various factors required and specified by the customers.

About The Author

Mr. C.N. Shukla, Training & Development Consultant, Pune Techtrol.

About Pune Techtrol

Pune Techtrol,a leader in designing and manufacturing the innovative Process Automation, Level measurement and Control instruments for liquids and solids. Used by many industries and professionals for more than three decades, Pune Techtrols’ quality equipment is trustedaround the globe.

For Information

Contact us at ho@punetechtrol.com

Visit us at www.punetechtrol.com