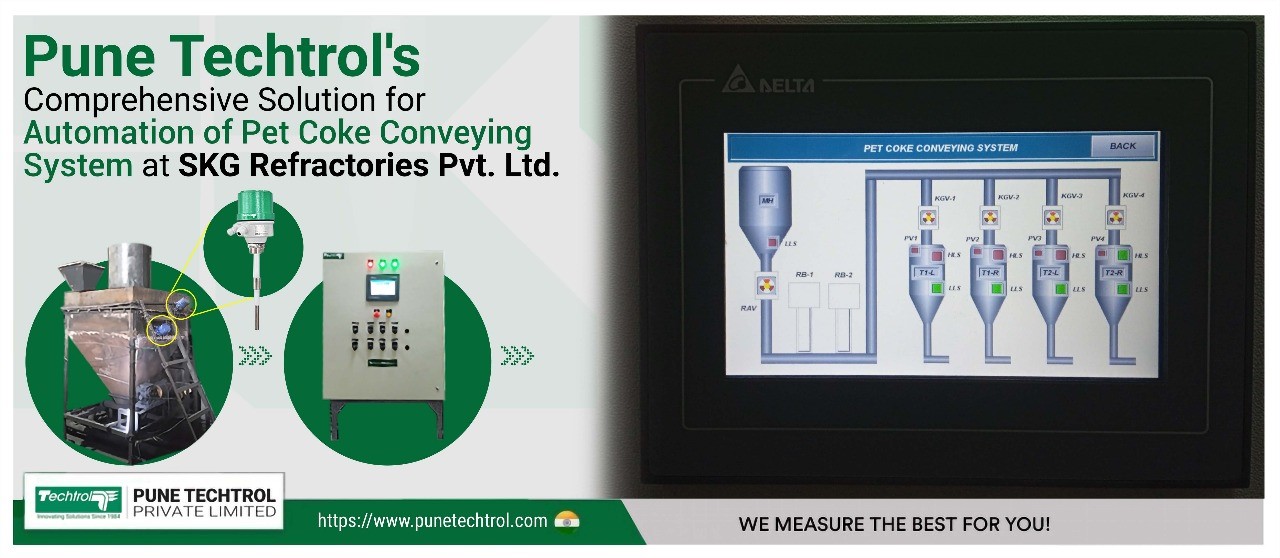

Best Solution for Clogged Chute Jam Detection in Mining Industry through Microwave Switch MWS

Introduction

Mining companies extract the metals from the ore in smelters with the crushed ore being transported over the conveyor via a feeding chute hopper for grinding into a fine powder. In the operation, the conveyor stops the moment chute is blocked, causing immense damage to process plant.

The Roadblock

All mining facilities occasionally face the problem of crushed ore clogging the chute hopper due to excessive flow, causing damage to conveyor & chute along with loss of material, during metal extraction. The Sesa Sterlite Ltd was continuously facing this problem resulting in plant downtime and an increase in production cost.

Although a conventional RF admittance switch was installed, it was not performing consistently, thus hindering their production operations.

The Solution

Pune Techtrol resolved the problem at Sesa Sterlite Ltd. by replacing their existing switch with a Microwave System.

The primary reason for switching to Microwave System was due to its accuracy, repeatability and immunity to high material build-up on the inner walls of chutes. Besides, being a non-contact type, it is non-invasive and requires minimal maintenance.

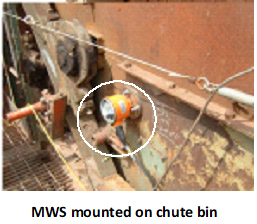

The installation comprises of a transmitter, which uninterruptedly emits a low power beam to the receiver. Both the transmitter and receiver are mounted apart, on opposite tank wall facing each other at max distance of 100 meters.

The switch once fitted will initiate the signal as soon as it detects chute jam caused by the excessive flow of material. It will work automatically to provide prompt control action through a relay contained in its receiver. Microwave switches are comparatively easy to retrofit on existing chutes & vessels.

The switch is multifunctional and can be optionally used for various applications like detecting presence and absence of material inflow and no-flow conditions, point level detection, proximity switch detection for reversing vehicles such as quarry trucks & railcars.

Result

The Microwave Switch System has helped Sesa Sterlite Ltd to carry on production uninterruptedly since 2010 and Pune Techtrol has retrofitted many Microwave Switch System on their other existing installations.

-

Boosting Boiler Safety with Bicolor Transparent Level Gauge Replacing Reflex Gauge

-

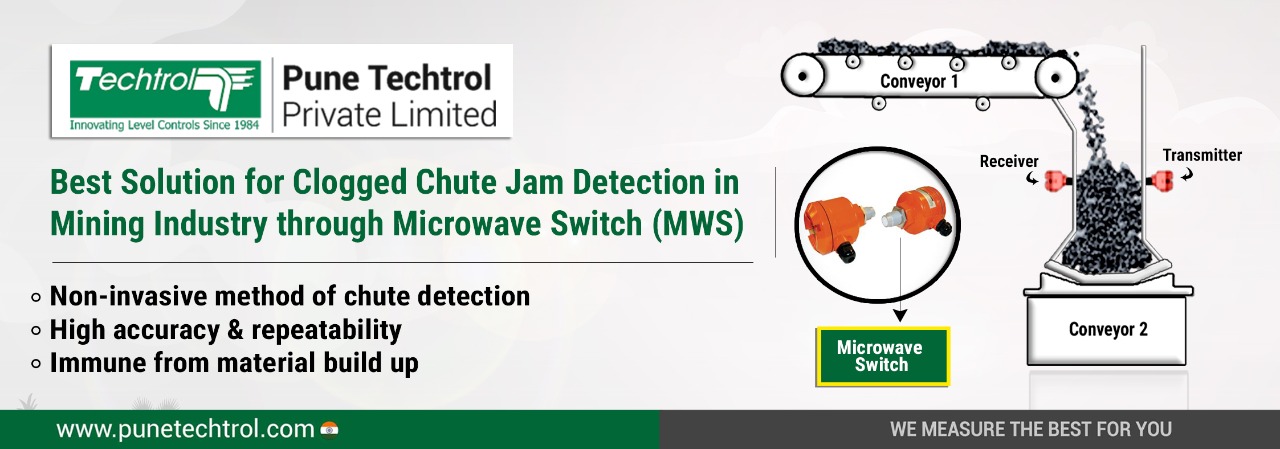

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

-

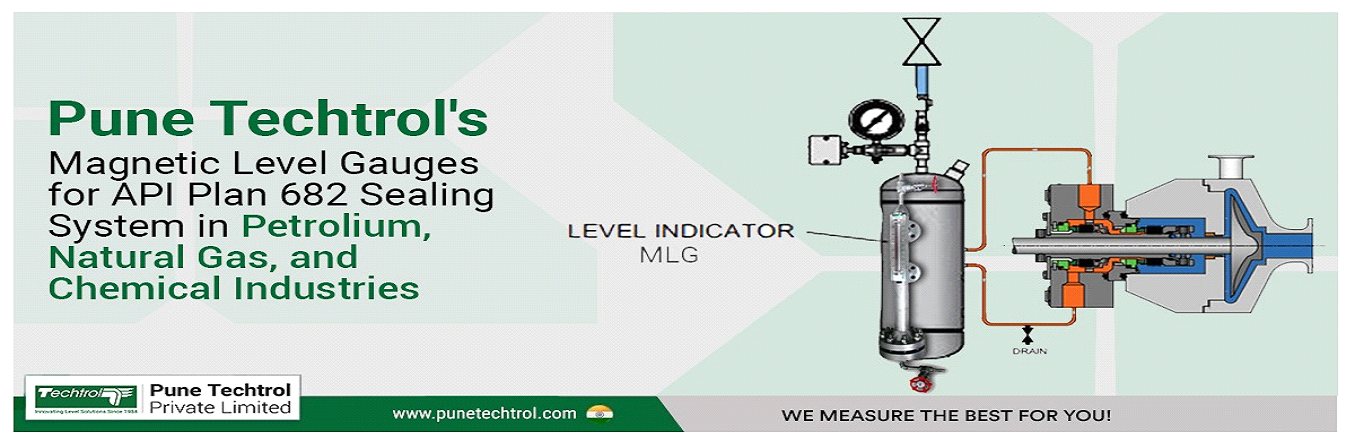

Comprehensive Solution for Automation of Pet Coke Conveying System at SKG Refractories Pvt Ltd

-

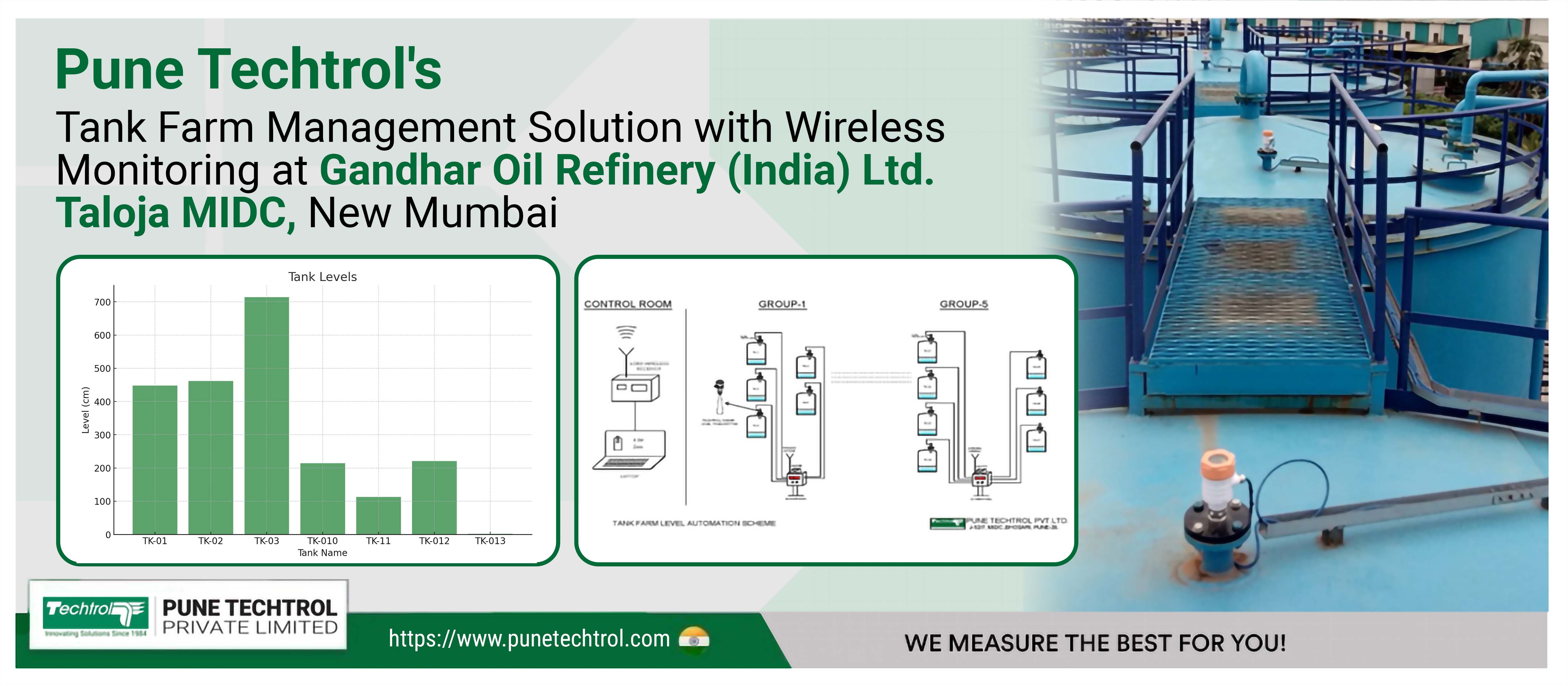

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

-

Pune Techtrols RF Wireless Remote Inventory Monitoring and Automation Solution for JSW Energy Ltd

-

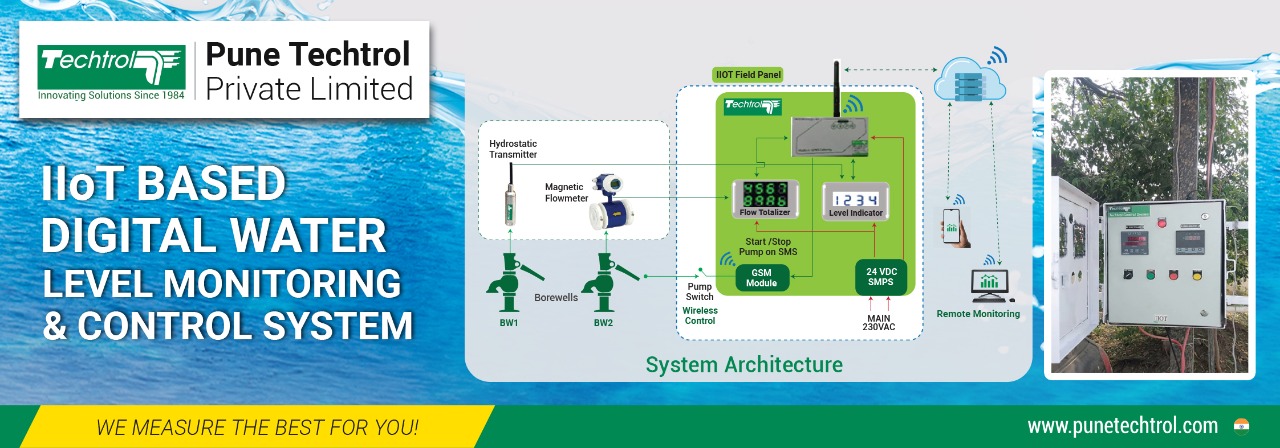

IIoT BASED DIGITAL WATER LEVEL MONITORING AND CONTROL SYSTEM

-

Pump Automation through Unitrol Level Switch

-

Level Automation of Concrete Mixer Silo at Green Building Products

-

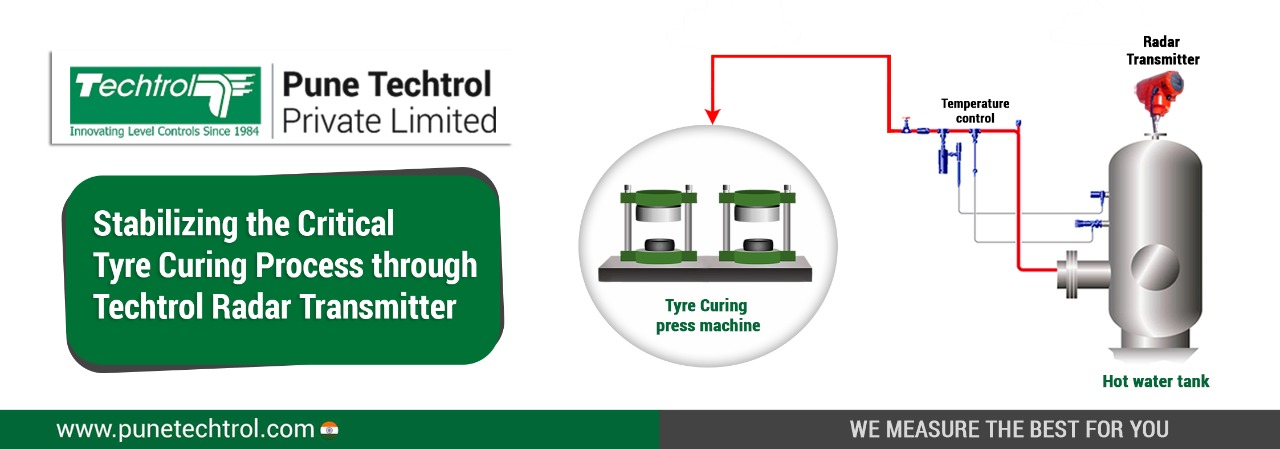

Stabilizing the Critical Tyre Curing Process through Techtrol Radar Transmitter