Boosting Boiler Safety with Bicolor Transparent Level Gauge Replacing Reflex Gauge

INTRODUCTION

Accurate level measurement in steam boilers is crucial for plant operators to ensure safe and efficient operation in process industries. The glass gauges have proven their reliability over time, and are widely used boilers to provide water level indication both above and below the normal water level. Gauge glass levels are treated with the utmost respect, as they are the only visual indicator of water level inside the boiler.

CHALLENGE

The boiler was equipped with a reflex level gauge for water level indication. The user approached us for a solution which offers better visibility from a distance alongwith solution for remote indication in the control room.

SOLUTION

After detailed discussion with the plant in-charge, the decision was made to replace the old reflex gauge with our Bicolor Transparent Level Gauge (BTFG). This upgrade ensures clear, accurate, and reliable level indication. BTFG with its illuminating system provides distinct indication of water level in green color and steam in red color which facilitate easy, unmistakable and safer level indication from distance.

For remote indication, advised to use CCTV camera for remote indication of boiler level

RESULT

Since its installation two years ago, the Bicolor Transparent Level Gauge (BTFG) has been delivering superior, uninterrupted performance. It has significantly reduced the exposure of boiler attendants to the boiler environment by providing clear and easily readable level indication from a distance. The user is highly satisfied with the solution provided by our technical team, leading to repeat orders for the same application.

-

Boosting Boiler Safety with Bicolor Transparent Level Gauge Replacing Reflex Gauge

-

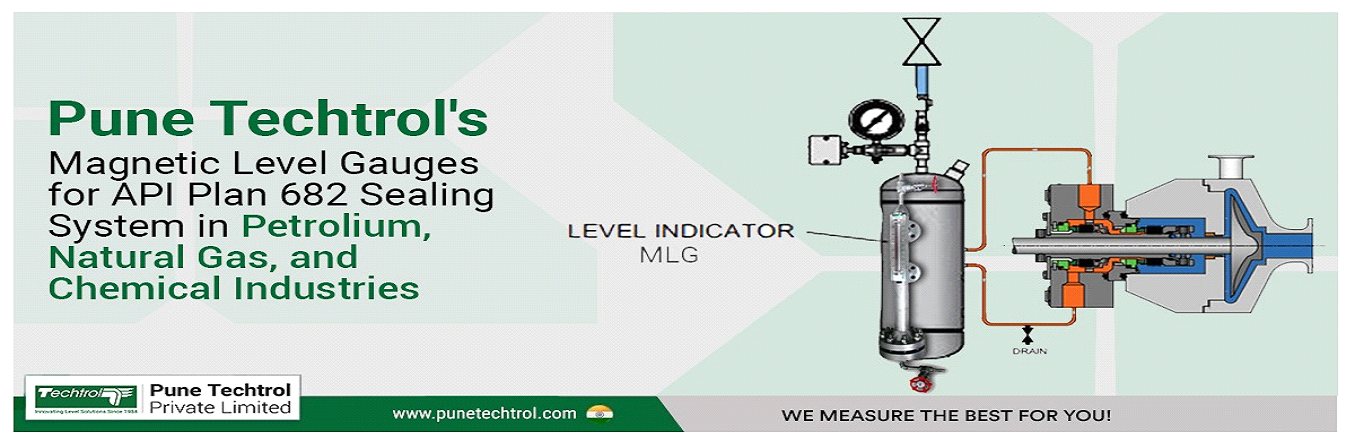

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

-

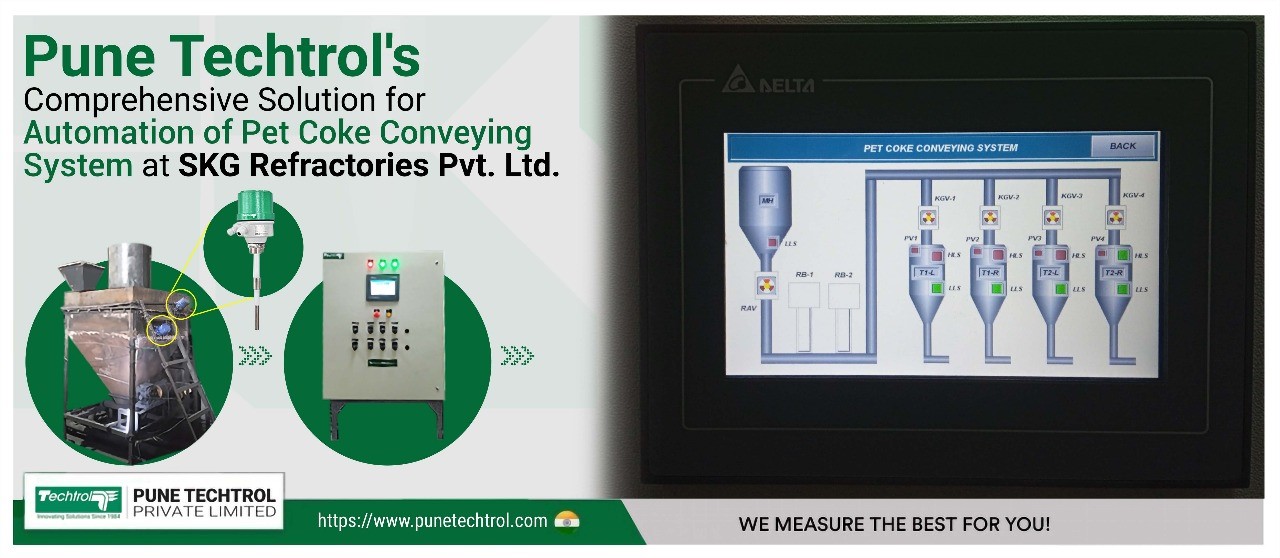

Comprehensive Solution for Automation of Pet Coke Conveying System at SKG Refractories Pvt Ltd

-

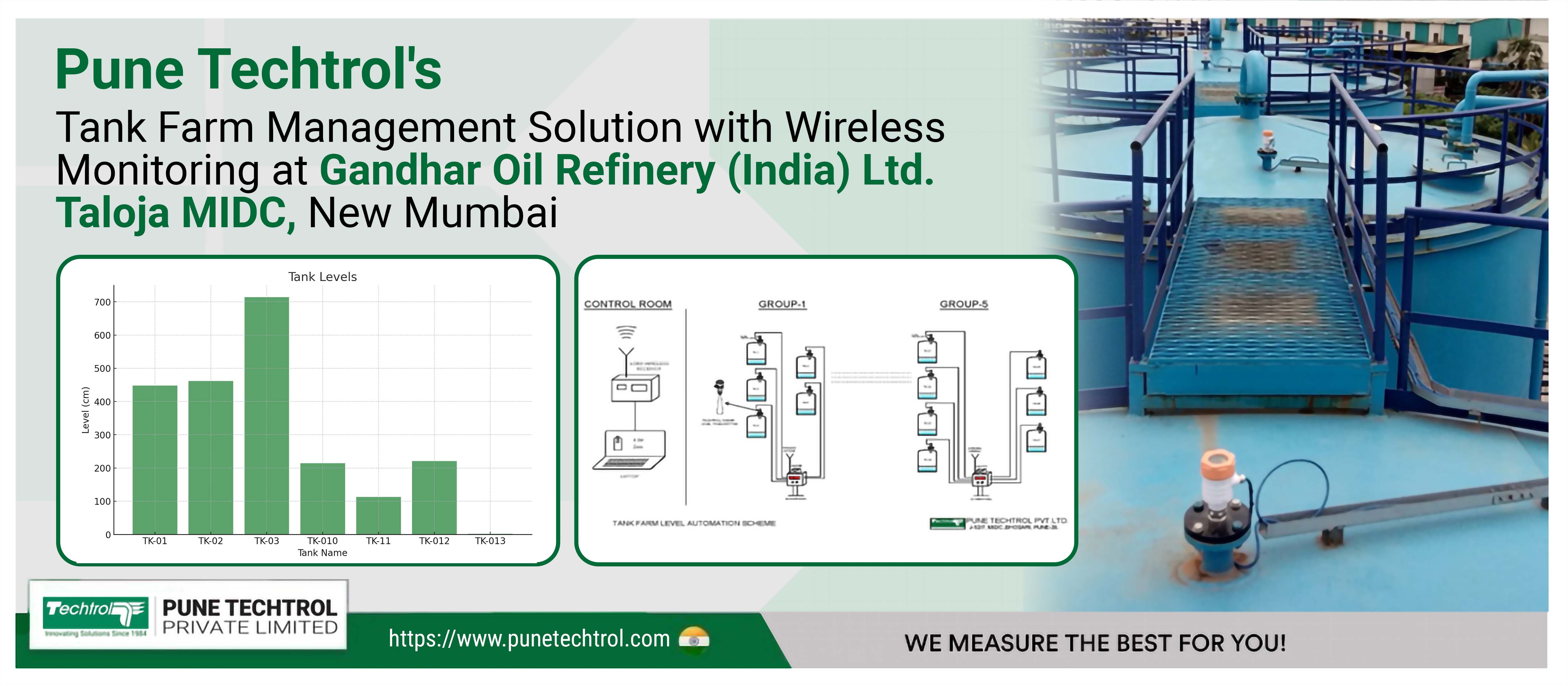

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

-

Pune Techtrols RF Wireless Remote Inventory Monitoring and Automation Solution for JSW Energy Ltd

-

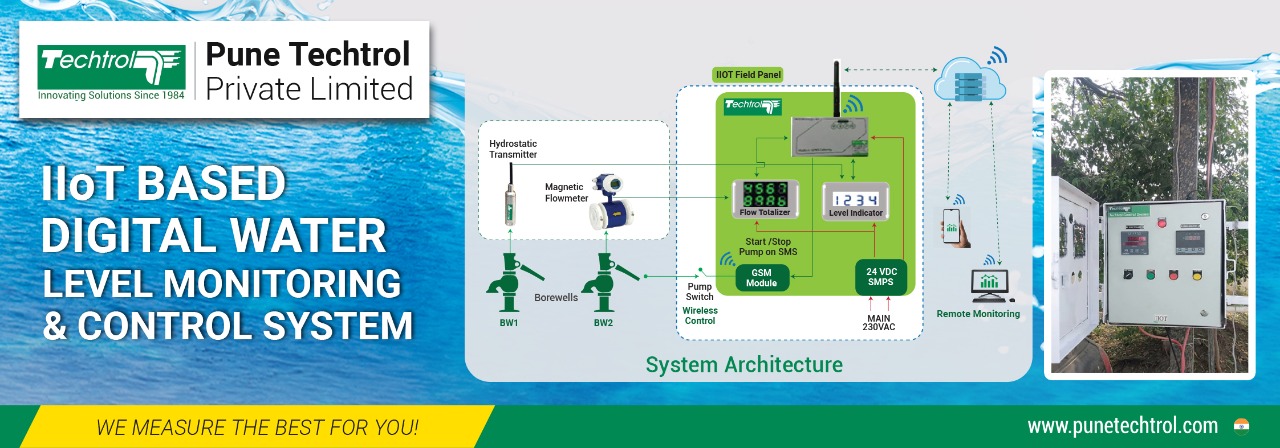

IIoT BASED DIGITAL WATER LEVEL MONITORING AND CONTROL SYSTEM

-

Pump Automation through Unitrol Level Switch

-

Level Automation of Concrete Mixer Silo at Green Building Products

-

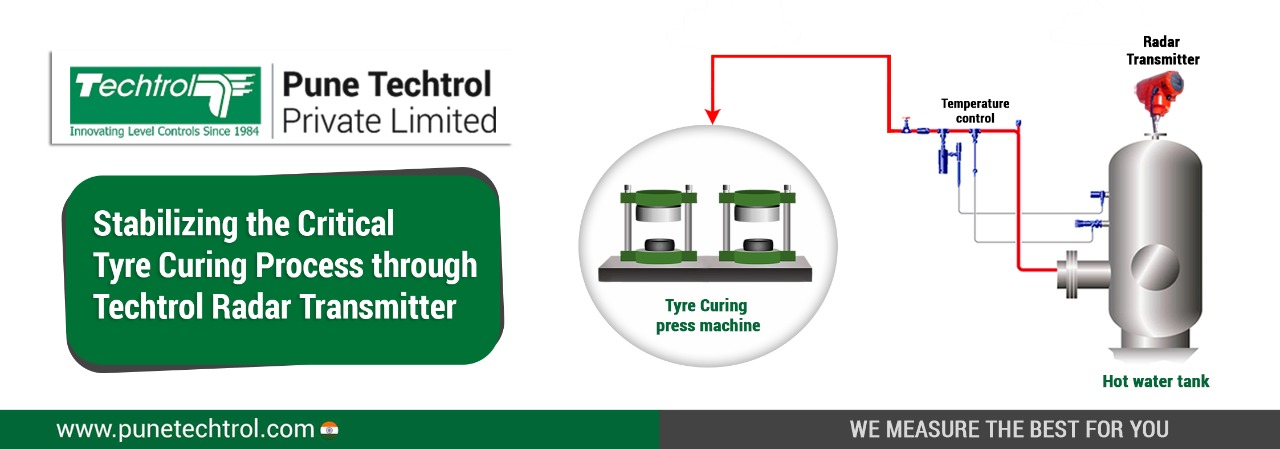

Stabilizing the Critical Tyre Curing Process through Techtrol Radar Transmitter