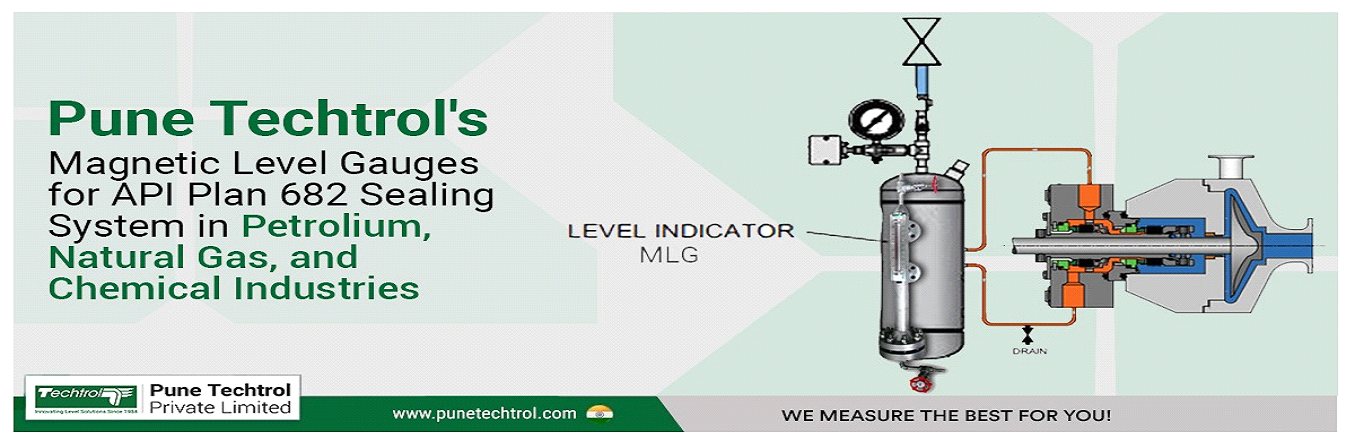

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

INTRODUCTION

Level measurement systems are vital in sealing applications for ensuring safety, operational reliability, reduced environmental impact, and cost efficiency. API seal plans are extensively adopted in refinery pump operations to improve the performance and reliability of mechanical seals. Among these, API Plan plays a crucial role in maintaining a buffer fluid in a reservoir at a pressure slightly lower than the process fluid. This design prevents process leakage, ensuring smooth, safe, and efficient operations in demanding industrial environment.

CHALLENGE

A reputed client in the oil and gas sector approached Pune Techtrol for a high-pressure level gauge suitable for a buffer fluid reservoir as per API Plan 682. The solution required adherence to strict design and performance standards to ensure reliability in high-pressure and chemically aggressive environments. Specific challenges included:

The ability to handle extreme pressures without compromising operational accuracy and safety.

Delivering precise level measurements in a harsh environment exposed to corrosive hydrocarbon-based fluids.

SOLUTION

The engineering team at Pune Techtrol recommended the High-Pressure Magnetic Level Gauge as the ideal solution for the client’s needs. These gauges are meticulously designed to cater to critical applications and offer:

High-pressure capability: Robust design to withstand pressures of up to 1500#, ensuring safe operation under challenging conditions.

Durability and compliance: Manufactured and designed as per API, ASME, and PED standards, ensuring superior performance in corrosive and harsh environments.

Reliable performance: Magnetic float technology enables accurate and consistent level readings, even in extreme operating scenarios.

RESULT

The gauges we supplied have been performing exceptionally well, meeting all the customer’s expectations. Our solution not only met but exceeded the customer’s expectations. The continued trust and satisfaction from the client affirm our commitment to delivering high-quality, engineered solutions for critical applications.

-

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

-

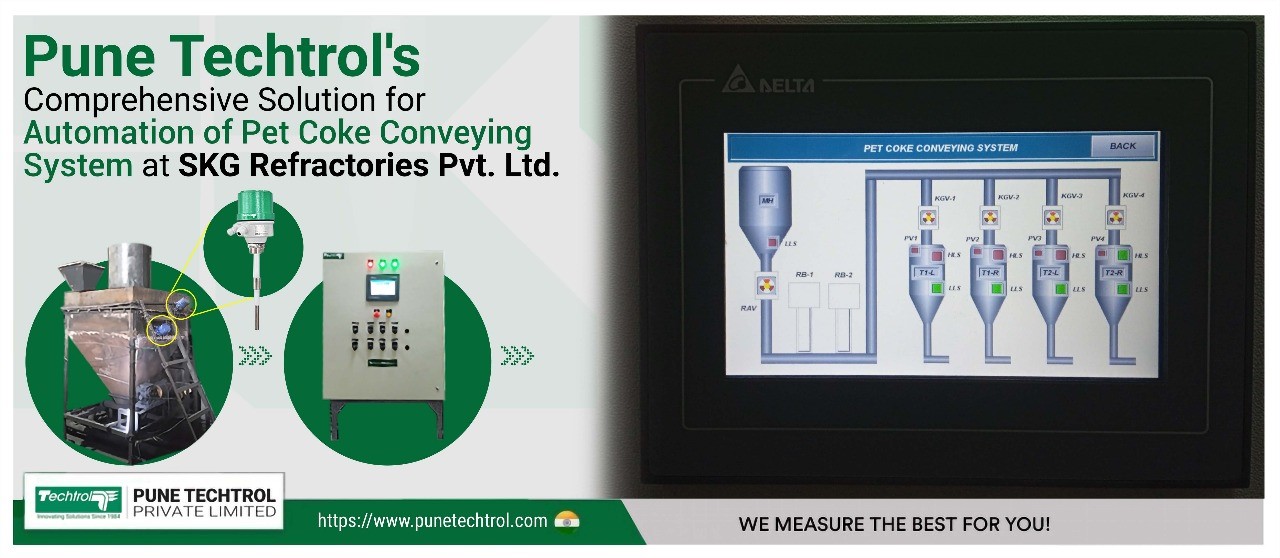

Comprehensive Solution for Automation of Pet Coke Conveying System at SKG Refractories Pvt Ltd

-

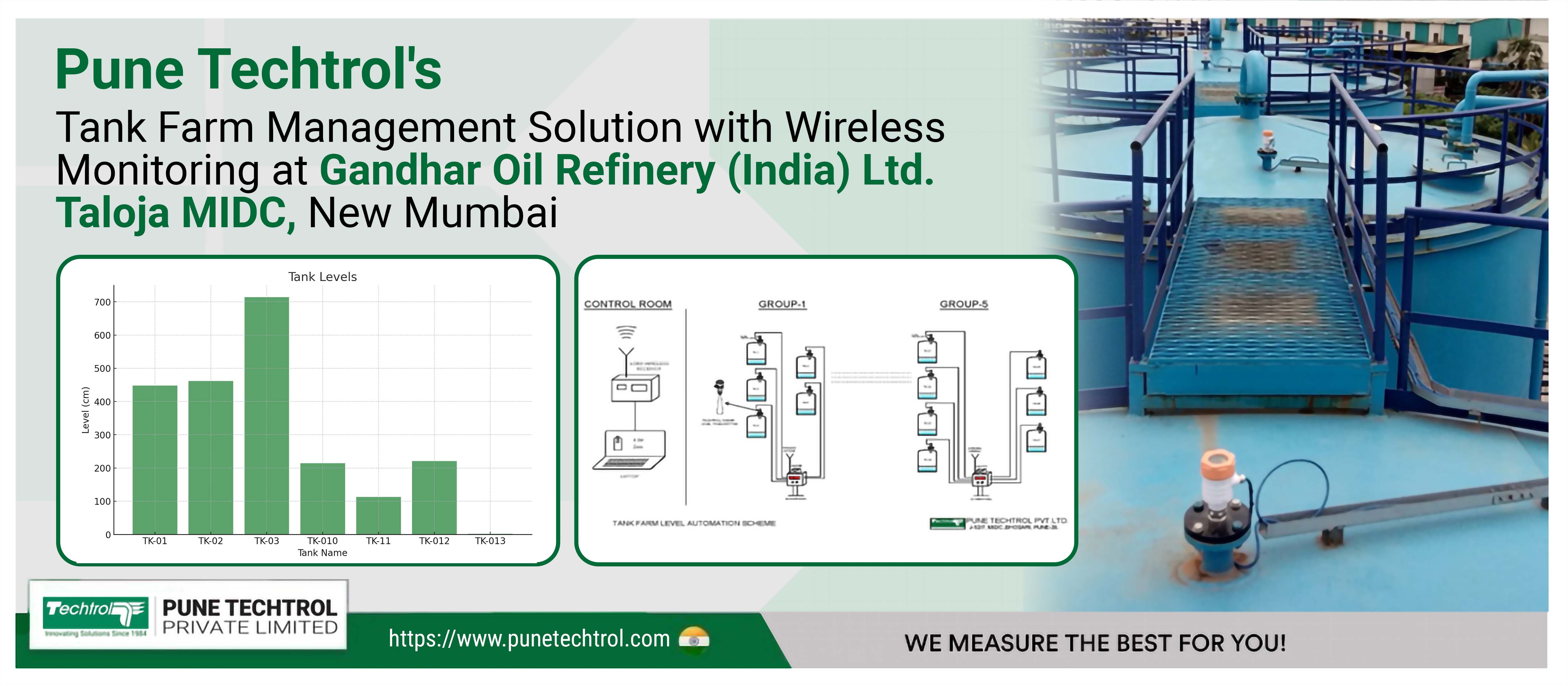

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

-

Pune Techtrols RF Wireless Remote Inventory Monitoring and Automation Solution for JSW Energy Ltd

-

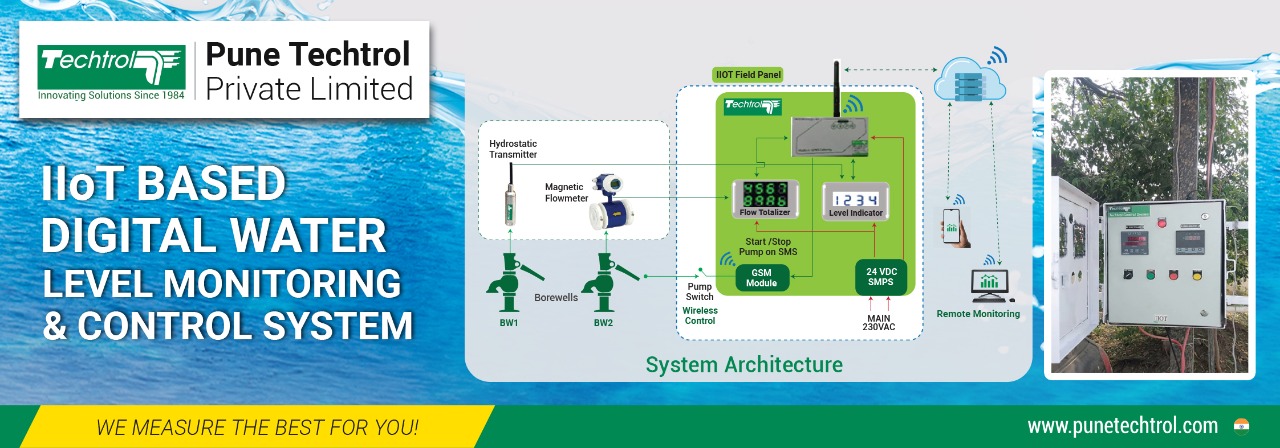

IIoT BASED DIGITAL WATER LEVEL MONITORING AND CONTROL SYSTEM

-

Pump Automation through Unitrol Level Switch

-

Level Automation of Concrete Mixer Silo at Green Building Products

-

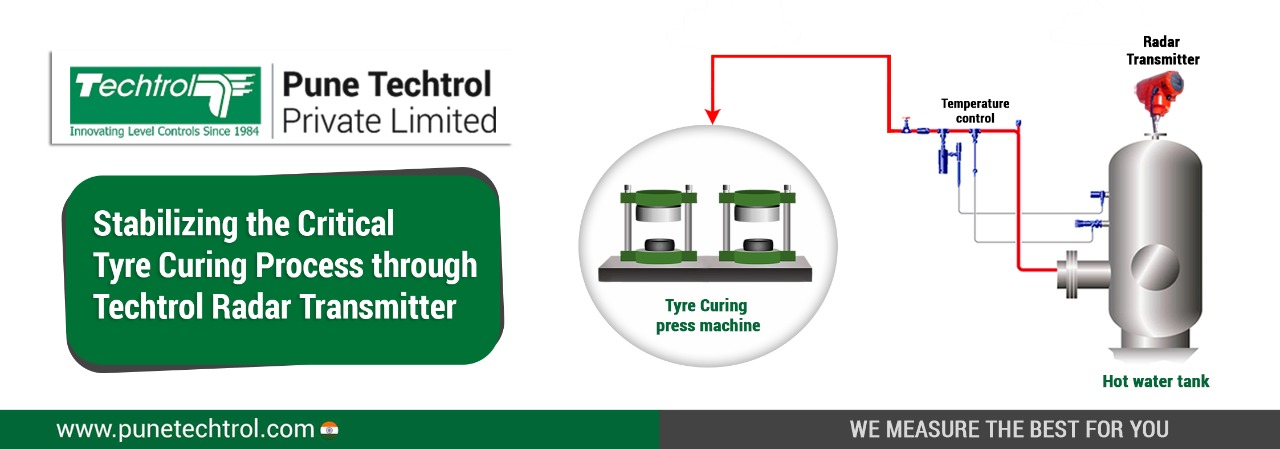

Stabilizing the Critical Tyre Curing Process through Techtrol Radar Transmitter

-

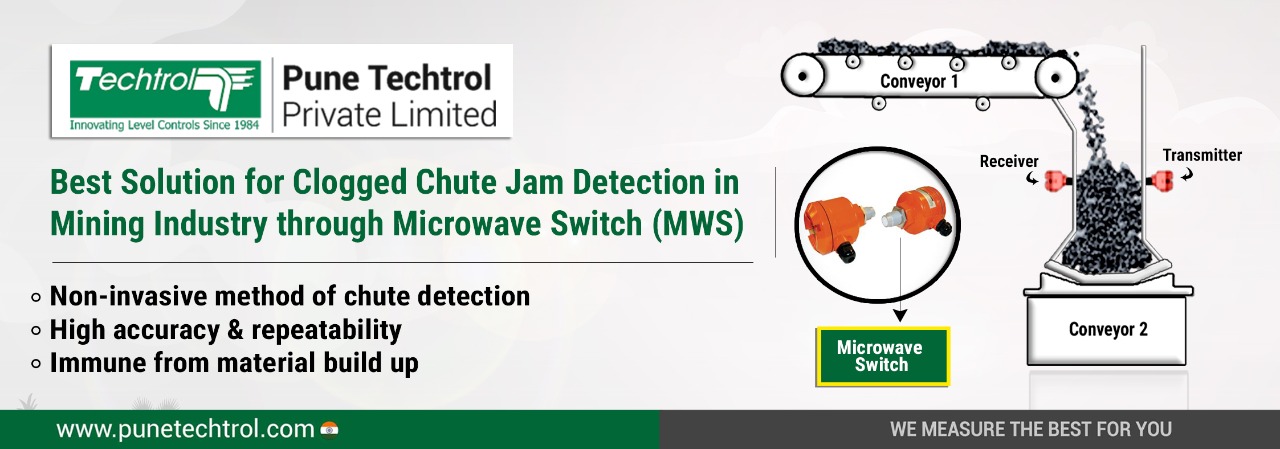

Best Solution for Clogged Chute Jam Detection in Mining Industry through Microwave Switch MWS