Successful Installation of Foam Detector at Tata Chemicals

Tata Chemicals is a well-known company in the field of industrial chemicals and branded agriculture & consumer products and they have also pioneered nutraceuticals for healthy and tasty modern food.

They faced a severe problem of extreme foam formation in their fermenter, containing a mixture of sugar solution, biomass & culture. The excess foaming resulted into heavy cost and reduced efficiency of the process, since large volume of foam occupies major portion of fermenter and chances of entering the foam in pipe lines and damage pump, which in turn caused increased down time. In spite of adding up the anti- foaming agent manually to restrict the foam formation, it led to intense consumption of expensive anti- foaming agent with low process yield.

They wanted to improve the process effectiveness to achieve cost savings in the use of anti- foaming agent. Pune Techtrol supplied Tata Chemicals with the solution, which was provided through the use of ‘Sure Sense.’ ‘Foam Detector’, consists of special probe with patented IMA Technology along with a control unit to automate the process of antifoam addition.

The probe was installed on the fermenter with adjustable process fittings which would sense the foam immediately on being formed. It makes the first move and gives signal to the control unit, which in turn would start/stop a dosing pump to control the flow of anti- foaming agent to the fermenter.

The concept of ‘Sure Sense’ has been working successfully which has resulted in incredible saving of anti- foaming agent and process downtime with reduced product wastage and increased batch size resulting in good quality return of the final product. This design of foam control is a recent phenomenon that Indian industries have witnessed and is speeding to catch up with it.

The application of ‘Sure Sense’ is used for foam control in water treatment plants, cooling towers, and process plants. An ultra-sensitive modification allows the foam detector to recognize very fine light foam to thick lathered foam.

-

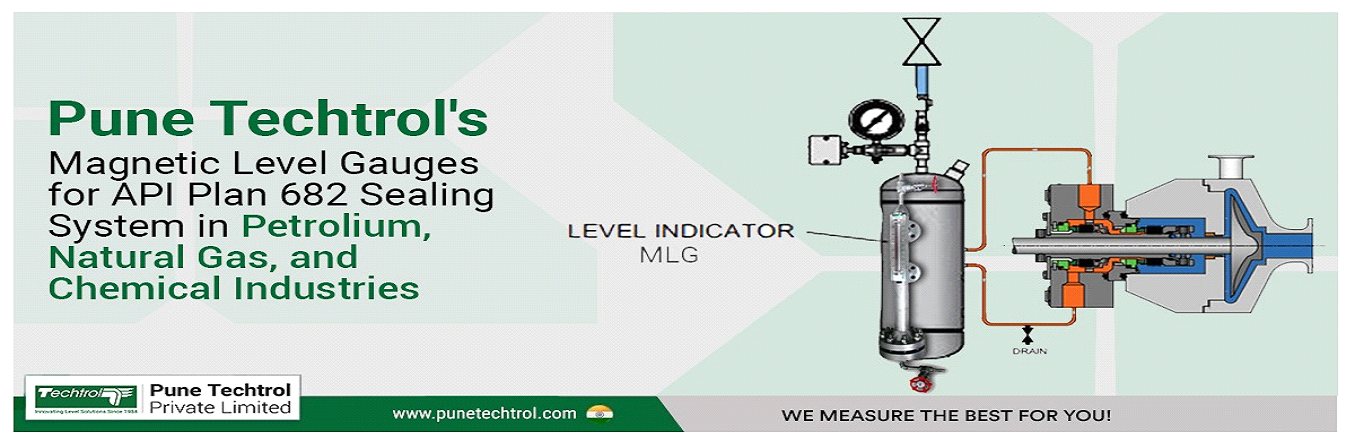

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

-

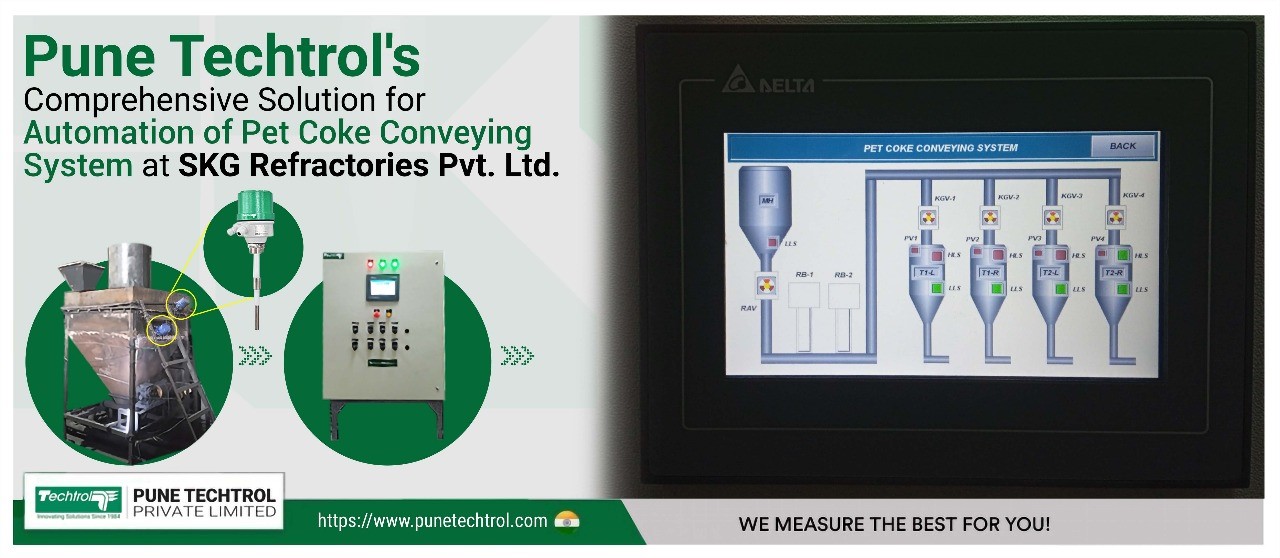

Comprehensive Solution for Automation of Pet Coke Conveying System at SKG Refractories Pvt Ltd

-

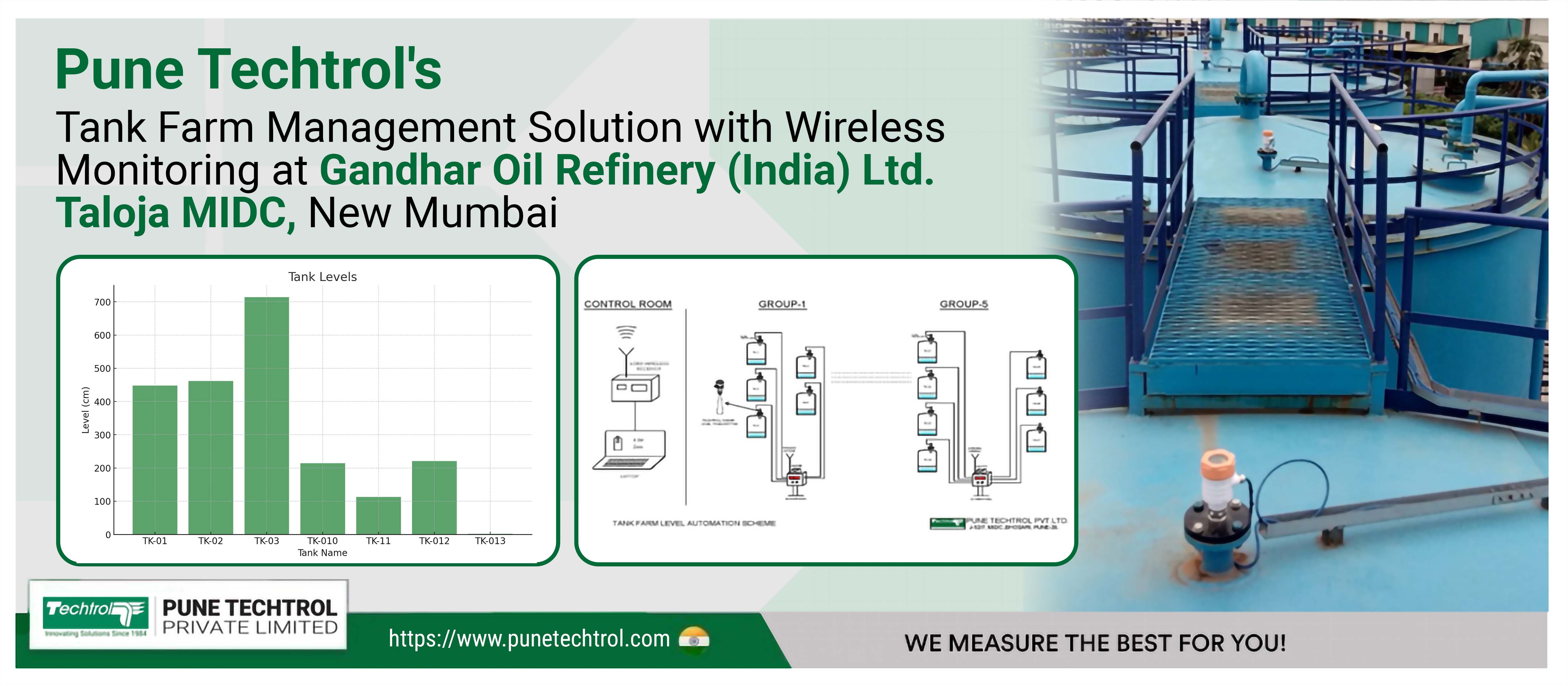

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

-

Pune Techtrols RF Wireless Remote Inventory Monitoring and Automation Solution for JSW Energy Ltd

-

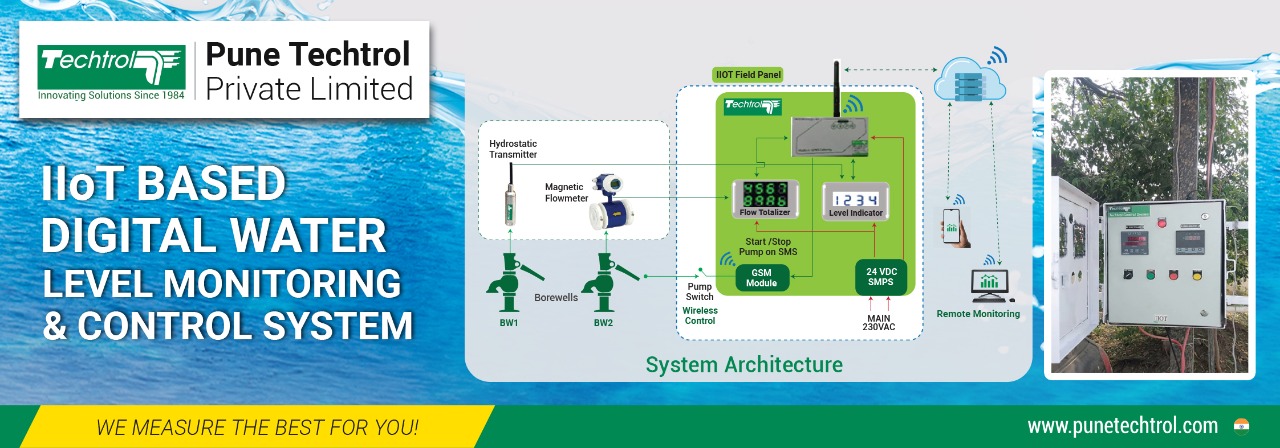

IIoT BASED DIGITAL WATER LEVEL MONITORING AND CONTROL SYSTEM

-

Pump Automation through Unitrol Level Switch

-

Level Automation of Concrete Mixer Silo at Green Building Products

-

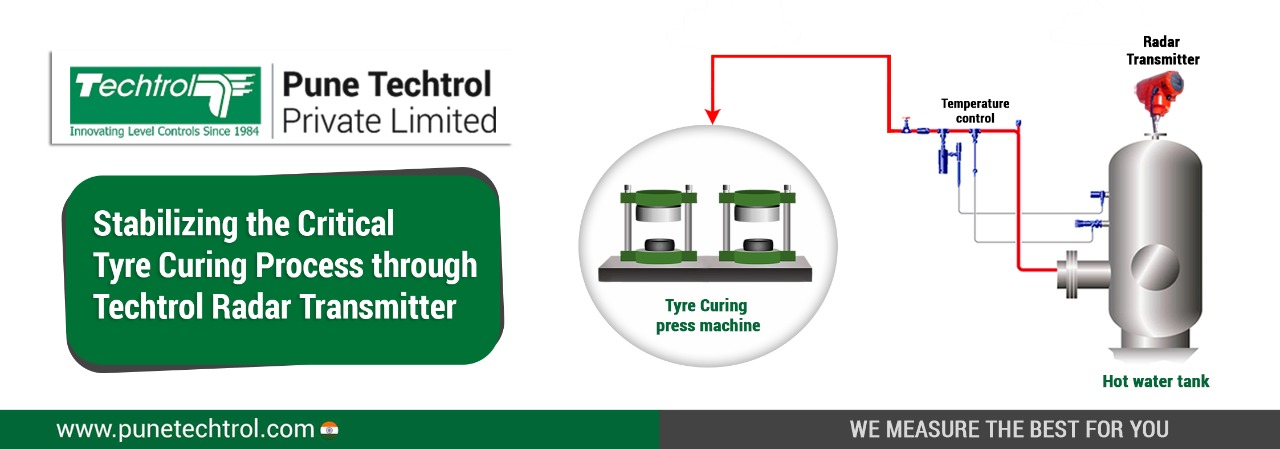

Stabilizing the Critical Tyre Curing Process through Techtrol Radar Transmitter

-

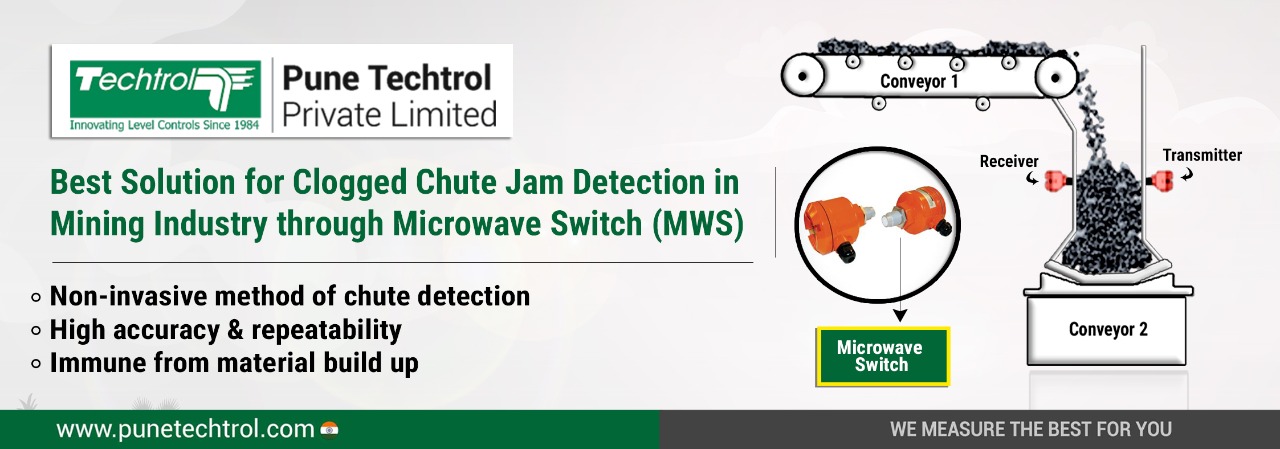

Best Solution for Clogged Chute Jam Detection in Mining Industry through Microwave Switch MWS