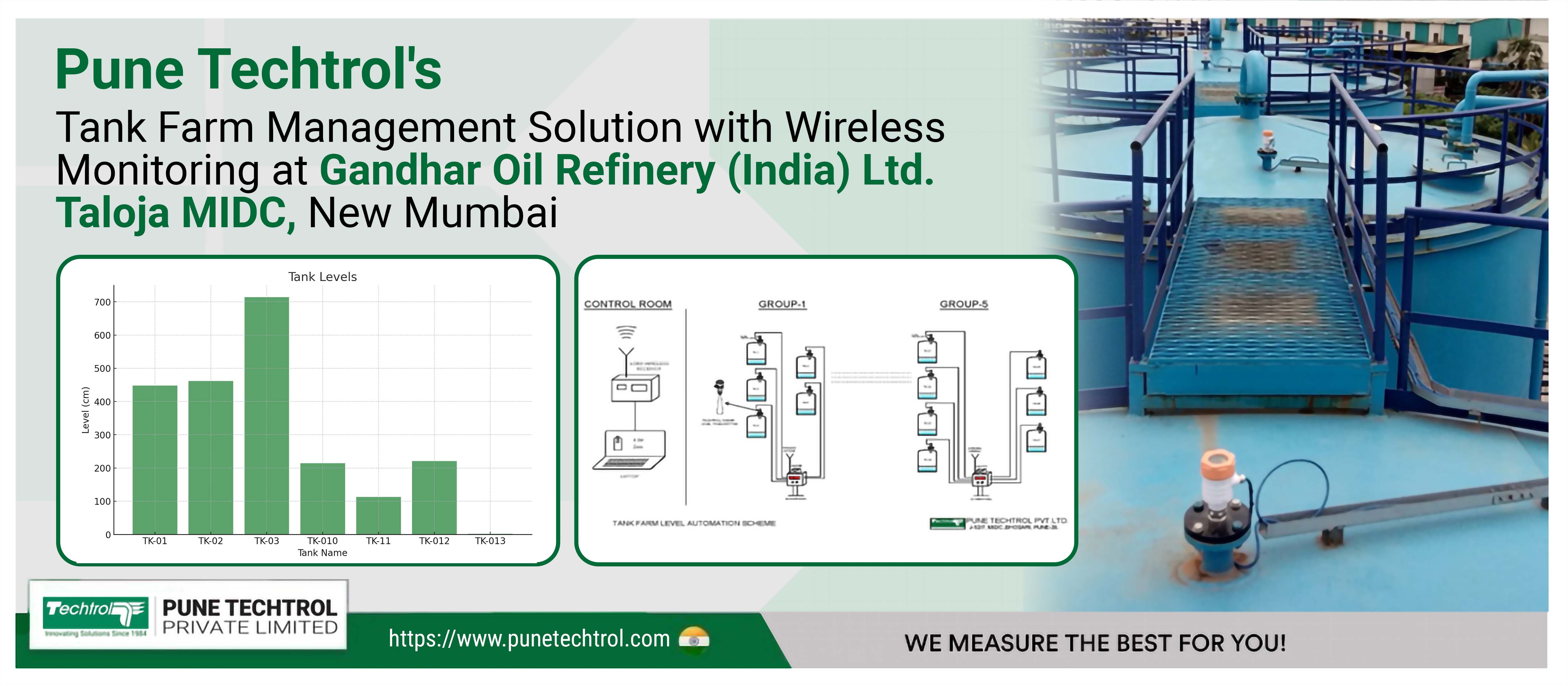

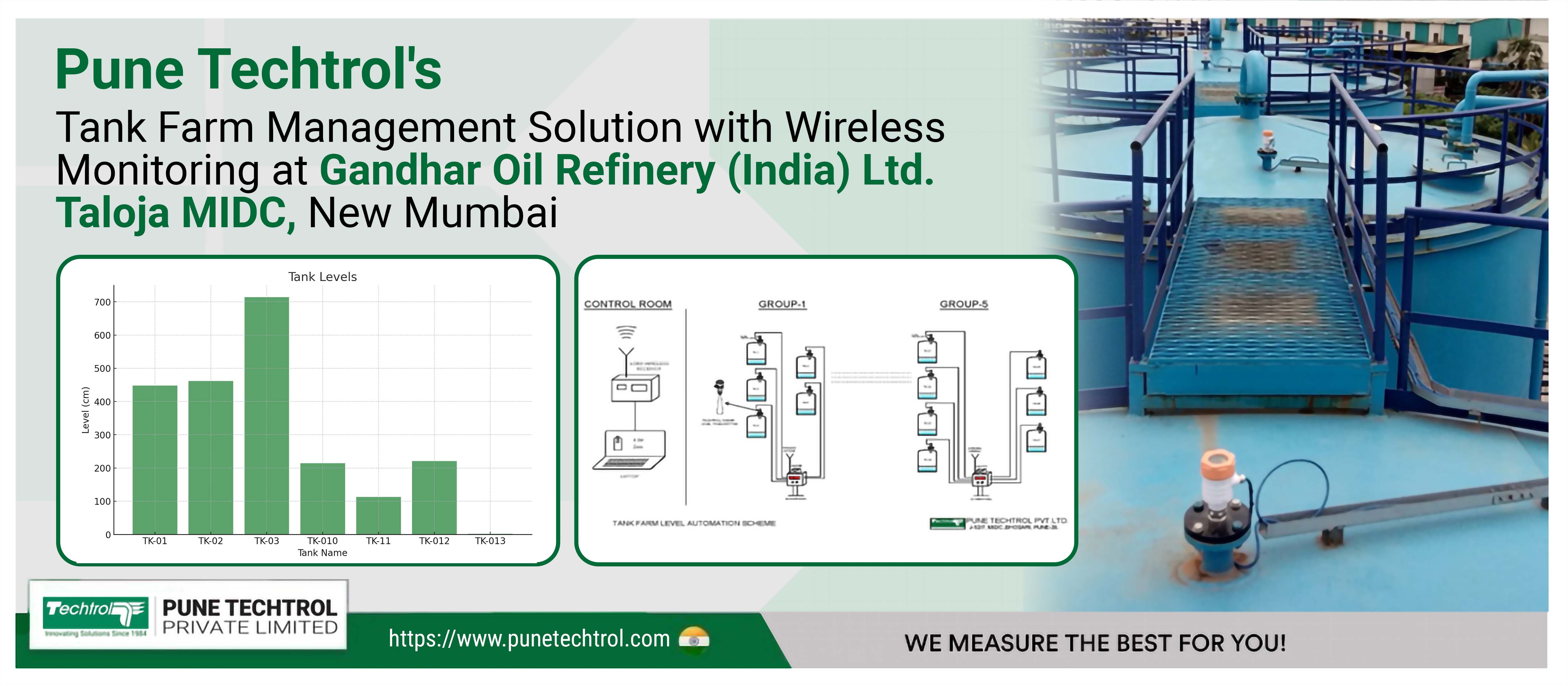

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

INTRODUCTION

Gandhar Oil Refinery, the flagship company of the Gandhar Group, operates three formidable Specialty Oil Blending Plants, strategically located in Taloja, Silvassa, and Sharjah. These facilities play a crucial role in the production processes, requiring precise and efficient tank farm management to ensure smooth operations.

THE ROADBLOCK

At the Taloja MIDC facility, the company faced significant challenges in managing its tank farm operations, consisting of 40 tanks approx. 15 meters in height. The manual dipstick readings used for daily level monitoring were tedious, time-consuming, and prone to inaccuracies, posing safety risks and delayed report generation. The complex process of reviewing and consolidating these reports required manual calculations, further consuming valuable time. Additionally, the facility needed continuous local level monitoring for loading and unloading, along with protection and warnings for high and low-level conditions to enable prompt corrective actions.

THE SOLUTION

To address these issues, Pune Techtrol proposed a comprehensive automation solution:

Replacing the manual dipstick method with Non – Contact Radar Level Transmitter sensing for accurate and reliable continuous level monitoring along with Tank Farm Monitoring System which includes RF transmitter and receiver, a web-based SCADA system. The system enables real-time report generation, eliminating the delay associated with manual reporting and audiovisual alarm for high and low-level conditions.

THE RESULT

Since its implementation in 2022, the new tank farm management system has provided Gandhar Oil Refinery with a cost-effective, efficient and safe solution, ensuring accurate and timely monitoring of tank levels. The system's performance has been exceptional, leading the customer to place additional orders for similar applications on more tanks. This success story underscores the substantial operational improvements realized through the innovative solution.

-

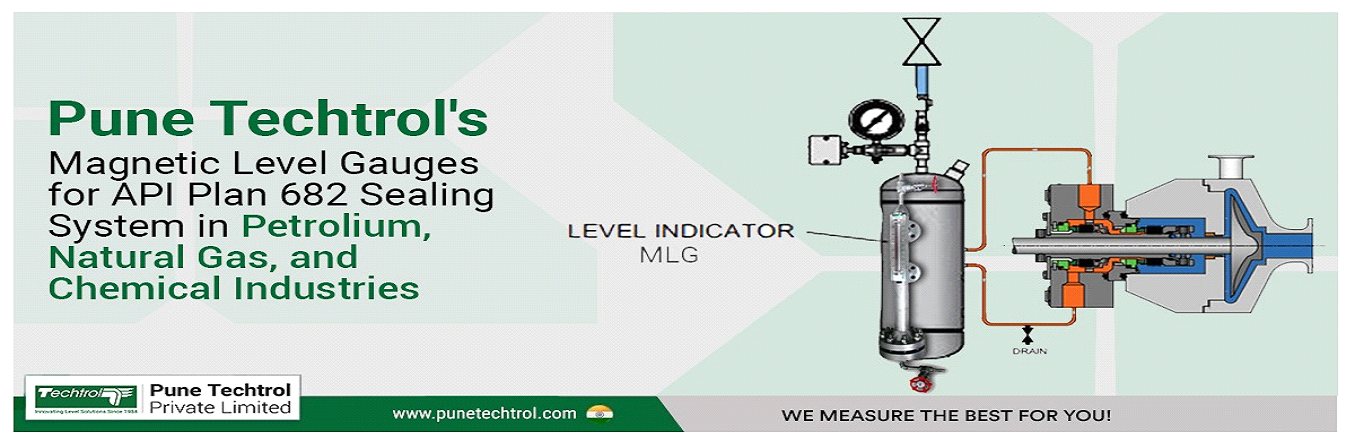

Magnetic Level Gauges for API Plan 682 Sealing System in Petrolium and Natural Gas and Chemical Industries

-

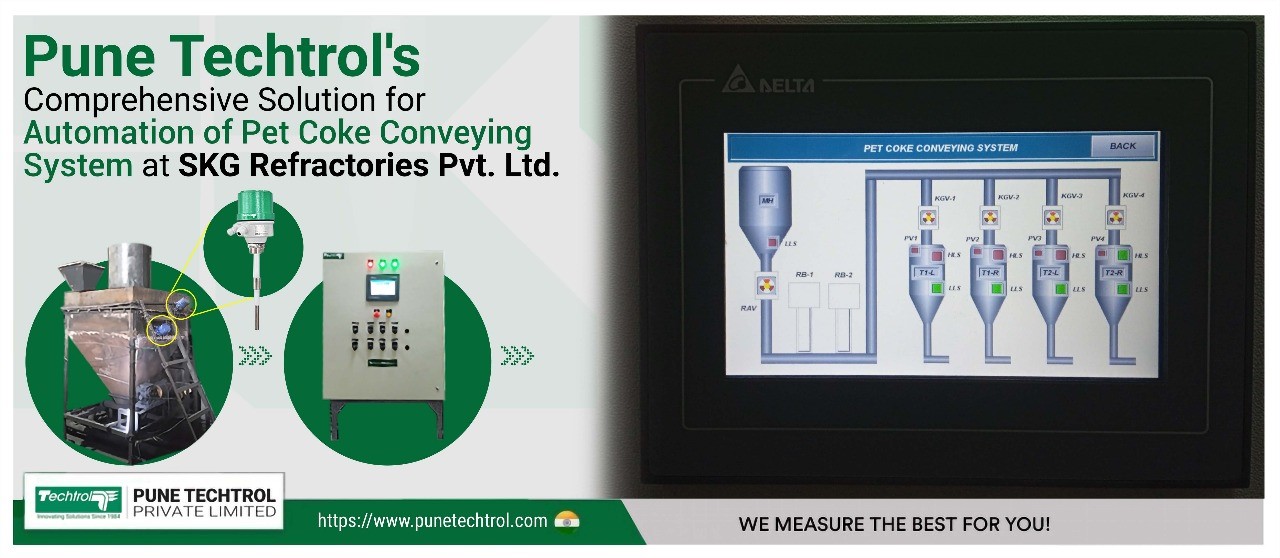

Comprehensive Solution for Automation of Pet Coke Conveying System at SKG Refractories Pvt Ltd

-

Tank Farm Management Solution with Wireless Monitoring at Gandhar Oil Refinery India Ltd Taloja MIDC New Mumbai

-

Pune Techtrols RF Wireless Remote Inventory Monitoring and Automation Solution for JSW Energy Ltd

-

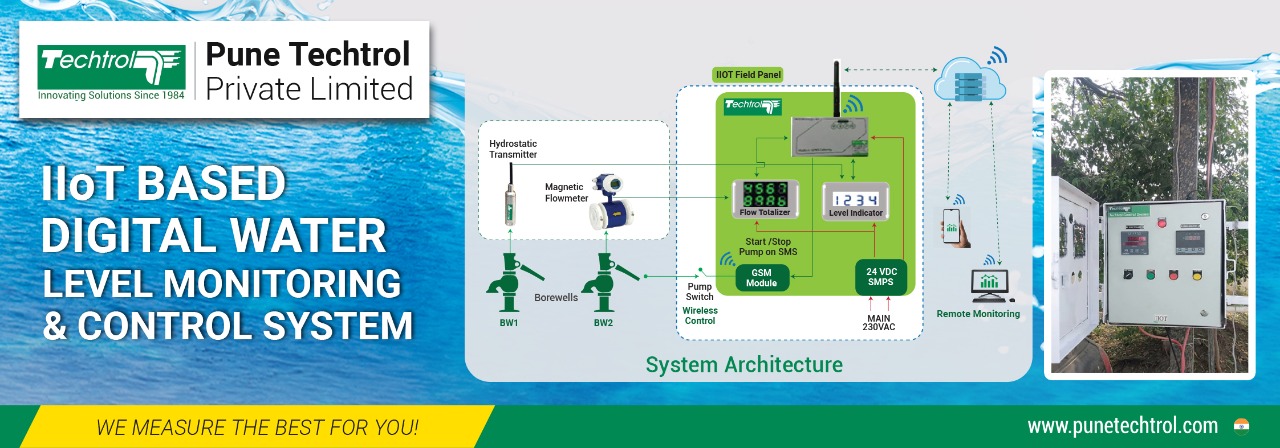

IIoT BASED DIGITAL WATER LEVEL MONITORING AND CONTROL SYSTEM

-

Pump Automation through Unitrol Level Switch

-

Level Automation of Concrete Mixer Silo at Green Building Products

-

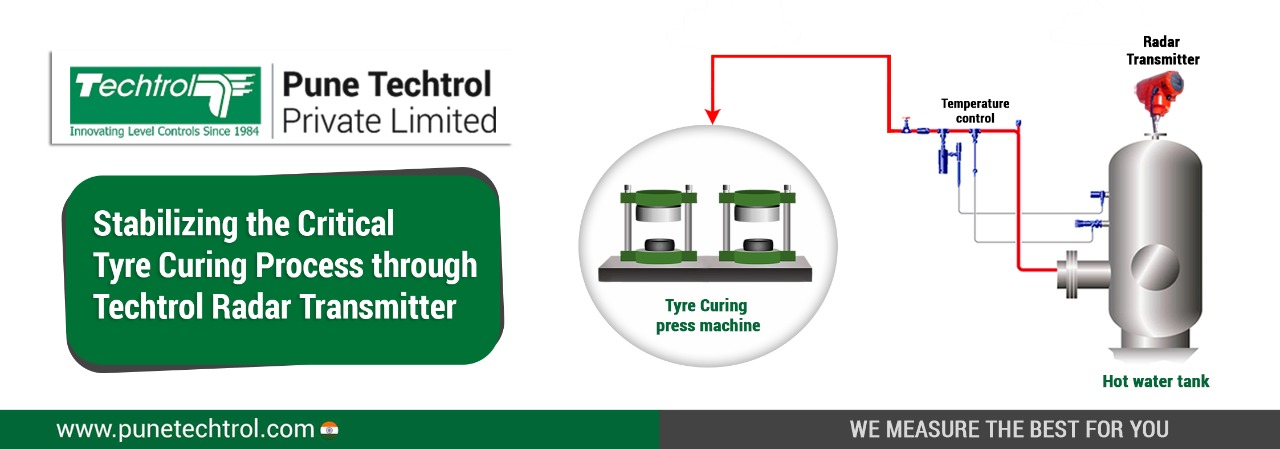

Stabilizing the Critical Tyre Curing Process through Techtrol Radar Transmitter

-

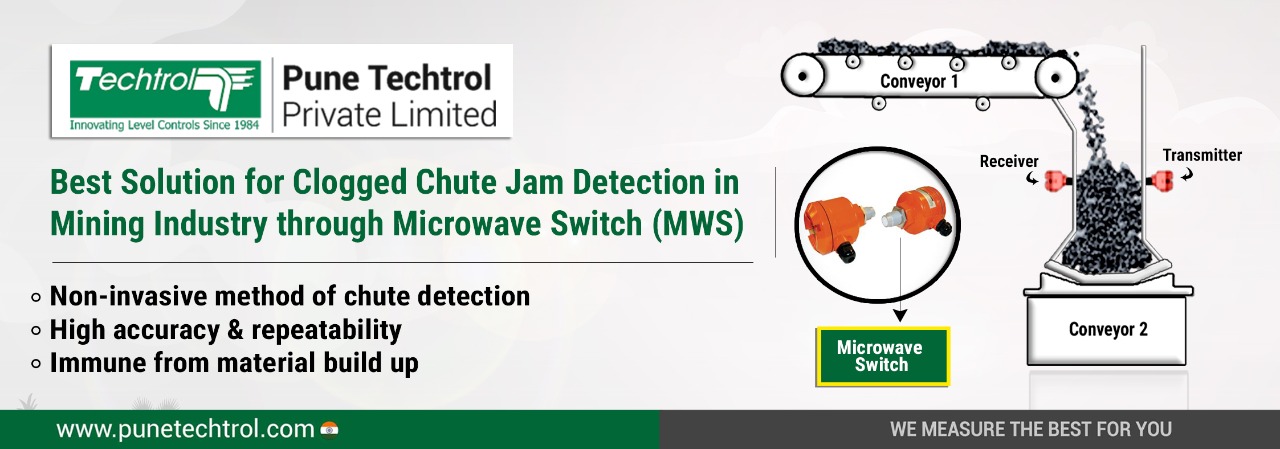

Best Solution for Clogged Chute Jam Detection in Mining Industry through Microwave Switch MWS